-

VetroSafe® Guardian OTG + VSF Shade #3 Lens

Vendor:VetroSafeRegular price $84.95 USDRegular priceUnit price per -

VetroSafe® Defender + VSF Shade #3 Lens

Vendor:VetroSafeRegular price $94.95 USDRegular priceUnit price per -

VetroSafe® Guardian OTG + VSF Click2Shade #3-to-5 Split Lens

Vendor:VetroSafeRegular price $164.95 USDRegular priceUnit price per -

VetroSafe® Defender + VSF Click2Shade #3-to-5 Split Lens

Vendor:VetroSafeRegular price $184.95 USDRegular priceUnit price per -

VetroSafe® FlareFilter 52mm Didymium Clip-on Phone Filter

Vendor:VetroSafeRegular price $74.95 USDRegular priceUnit price per$84.95 USDSale price $74.95 USDSale -

VetroSafe with Custom Frame

Vendor:VetroSafeRegular price From $165.00 USDRegular priceUnit price per

What are Glassblowing Safety Glasses?

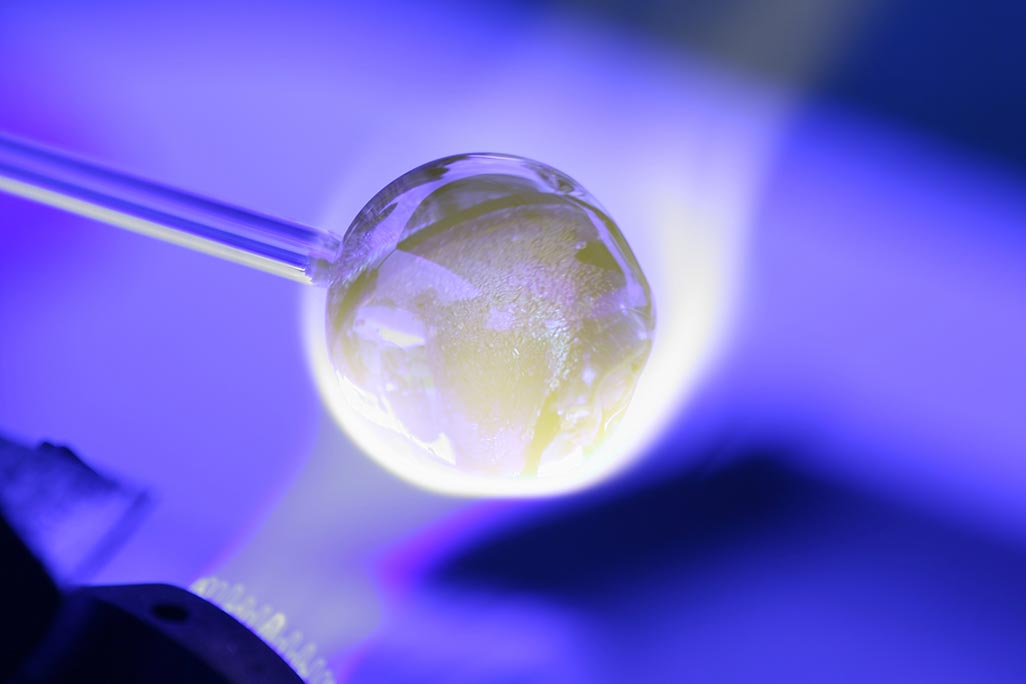

Glassblowing is a type of glasswork where air pressure is used to modify the shape of a hollow piece while heat is used to enhance the elasticity of the glass. The heat source may be from a kiln, or from a torch. Kilns apply a general heating to the entire piece while torches can be used to heat only a small area enabling the glassworker to create intricate and complex designs.

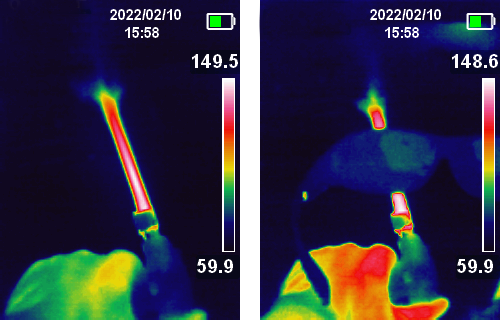

When applying heat with a kiln or a torch, the eyes may be exposed to a high intensity of invisible infrared light. For kiln workers the eyes are exposed to particularly high and dangerous levels of Infrared light when looking into the "glory hole", i.e., the entrance to the kiln. Over time this exposure can lead to the formation of "glassblower's cataracts" which will eventually require a surgical intervention to treat. Torchworkers generally experience less exposure to infrared radiation however the localized application of heat to the glass can result in a hot spot with considerable IR emission.

For classical "hot-shop" glassblowing using a kiln as the only heat source, the need for sodium flare blocking may not be relevant in which case any standard welding shade lens between Shade #3 to Shade #5 is usually sufficient for protecting the eyes. However, in some cases a hybrid technique may be practiced using both a kiln as heat source in combination with a torch for localized heating and working of the glass, such as when constructing larger sculptures with multiple components. Whenever a torch is involved, the need for glassblowing safety glasses that include sodium flare blocking is beneficial. Sodium flare blocking glasses are commonly used in lampworking, however many such products lack sufficient protection for the glassblower due to insufficient infrared light blocking.

The ideal type of safety glasses for use in glassblowing should include both infrared blocking and sodium flare blocking, thus enabling the use of the glassblowing to be used in a wide range of conditions and types of heat source. To be certain of sufficient infrared light protection, the safety glasses should meet or exceed ANSI/ISEA Z87.1-2020 standards for Shade #3 or higher.

Built from the ground up for safety and performance

VETROSAFE is an independent brand created by an eyewear industry veteran with over 10 years of experience in technical eyewear design. Our mission is to provide the best possible eye protection for hard (borosilicate) and soft (soda-lime) glass lampworking, torchworking and glassblowing/flameworking hybrid techniques with all-purpose safety eyewear product that exceeds ANSI/ISEA Z87.1-2020 standards for industrial eye protection

-

Welding Shade #3

The VETROSAFE U6L3R4-rated lens exceeds minimum standards for ANSI/ISEA Z87.-2020 Welding Shade #3 with R4 95% average infrared light blocking to enable use over a wide range of temperatures.

-

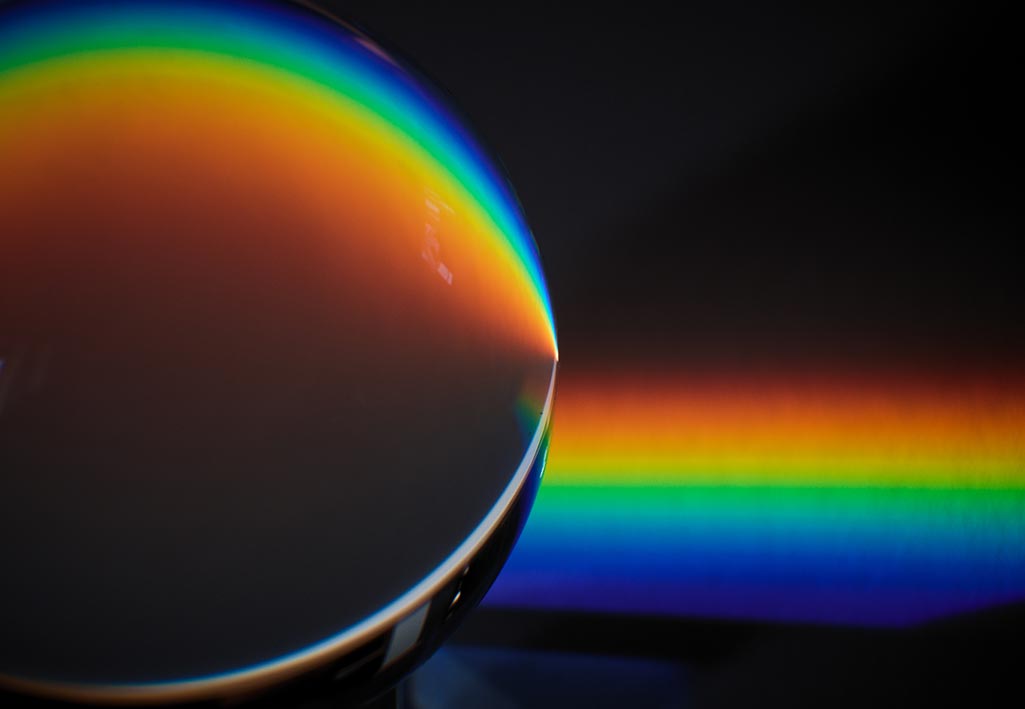

True Color Vision

Optimized color-corrected lens design with chromaticity white-point less than 0.01 xy units from neutral enables accurate color checking without interrupting workflow.

-

Sodium Flare Blocking

Precision wavelength-selective OD5+ sodium flare filter removes yellow light in torch flare for a clear view of the work piece during flameworking.

-

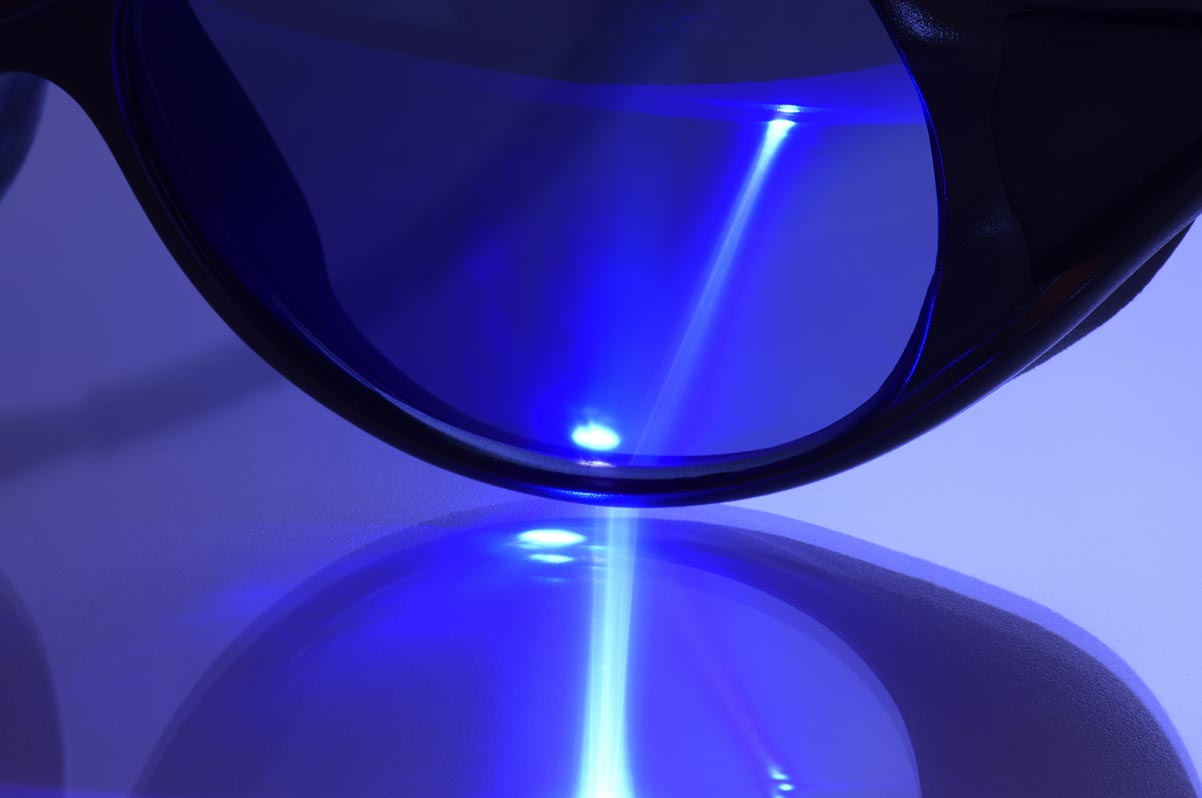

Blue-Light Filter

Industry-leading 420nm HEV blue-light filter reduces eye exposure to harmful high-energy blue-light emitted by burning hydrocarbons in the flameworking torch.

-

Z87+ Impact-Rated

Prepare for the unexpected with lens and frame made with industrial-strength high-impact plastic for maximum eye protection from every angle.

-

Multi-Coated Optics

Ophthalmic grade anti-reflection, super-hydrophobic and oleophobic coatings provide maximum visual clarity and an ultra low friction, easy-to-clean lens surface.

Eliminate Sodium Flare

Didymium glass has long been used by glass flameworkers to remove the veiling yellow light caused by super-heated sodium content in glass. VetroSafe's proprietary lens design takes eye protection to the next level by adding R4 infrared light blocking, UV blocking and HEV blue-light filtering for reduced eye strain and best-in-class ophthalmic safety.

Infrared Light Blocking

Traditional didymium glass lenses do not block infrared light in the 780-2000nm spectral band, requiring users to layer on additional welding filters for protection, resulting in added weight and darkened vision. VETROSAFE is designed from the ground up with 95% infrared blocking in a lighter, brighter and color-corrected lens design, enabling seamless worry-free use regardless of torch intensity.

Blue-Light Filtering

Harmful blue-light between 400nm to 420nm has been shown to damage sensitive structures deep in the eye, causing eye strain and diseases such as macular degeneration. These blue-light wavelengths are emitted by electronic transition bands called Swan Bands that are created by burning hydrocarbons in a flameworking torch. VETROSAFE delivers comprehensive >99% blue-light filtering up to 420 nanometers to guard against consequences of long term exposure to high-energy blue-light radiation.

True Neutral Color

VETROSAFE lenses are created using a mathematical design process to achieve unrivaled white-point color accuracy less than 0.01 xy units from neutral, enabling clear, natural color vision and an uninterrupted color creation workflow.

Founder's Note

Unlike glass artifacts whose inert characteristics enable preservation of the legacy of centuries of glass work, our eyes are among the most vulnerable of the sensory systems - the sensitive tissues of the eye can be easily damaged from over-exposure to light and often cannot be regenerated, resulting in diseases such as cataracts and macular degeneration. Unfortunately, due to the intense exposure to heat and light, glass flameworkers experience vision problems at rates much higher than the general population.

As a serial entrepreneur and inventor of functional eyewear products, I was disappointed by the continued use of outdated lens technologies for glassworkers’ eye protection, the confusing array of lens options suggesting a lack of coherent design thinking, and the use of escalating price schedules to gain access to protective features that should be standard. I created VETROSAFE to make a better option. With a single, fully optimized lens design, all of our glasses provide comprehensive protection from UV, sodium flare and infrared blocking combined with advanced blue-light filtering in an impact-rated frame, while simultaneously delivering a new standard for visible light transmission and color accuracy enabling the eyewear to be used in both soft and hard glasswork.

I hope this product will help to take your work to the next level. I would love to hear your feedback.

-- Andrew, Creator of VetroSafe